LabelRoll-F

26/11/2019

TRUPOINT ORANGE DOCTOR BLADE

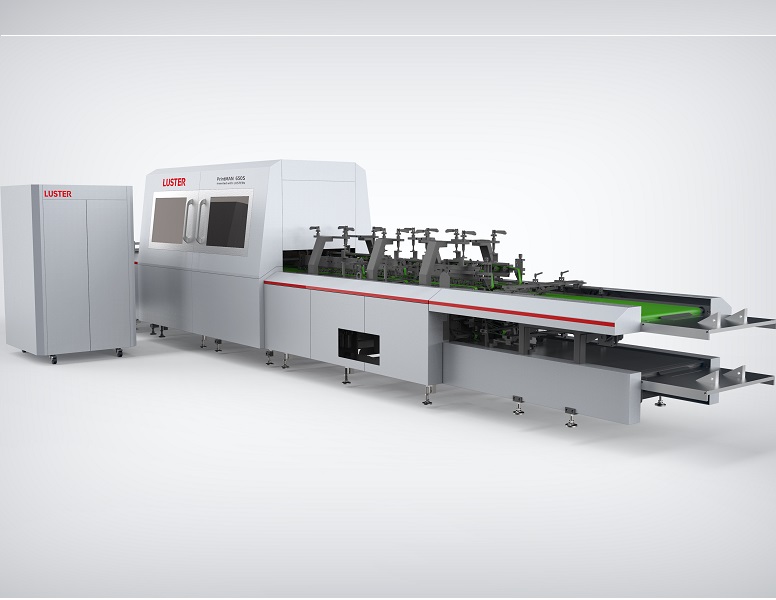

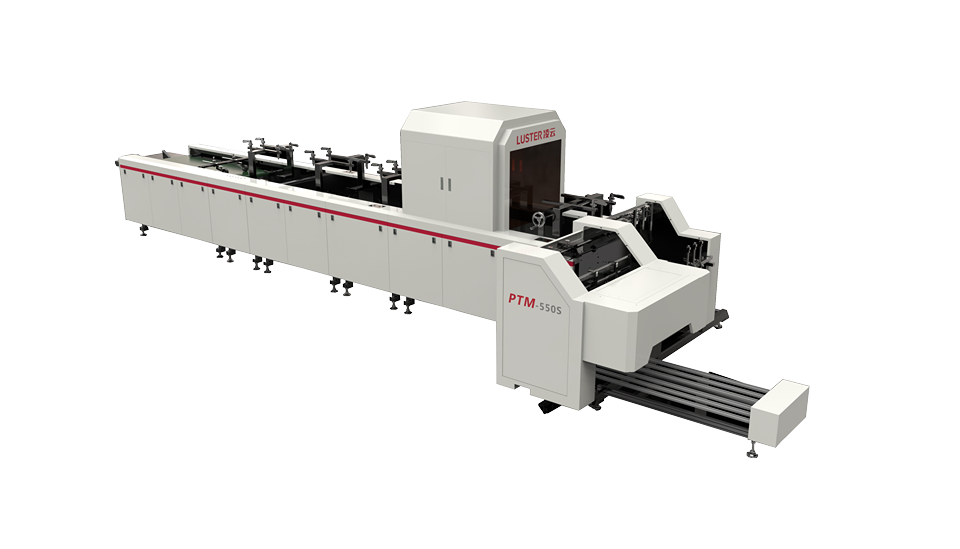

21/04/2020PrintMan

Specially developed for sheet-fed packaging inspection such as pharmaceutical packaging, tobacco packaging, 3C electronic products packaging, cosmetic packaging, food packaging, liquid packaging etc. Its wide adaptability allows accurate inspection of highly-reflective substrates as well as normal ones, for instance gold and silver paperboard, laser paperboard, aluminized material and stamping material. It is able to inspect defects like streak, missing print, dirty spot, splash, mis-registration, colour deviation as well as embossing defects. What’s more, it can provide effective inspection and classification of variable data.

Main Features

- Easy to Use

Only one reference image is needed for setting up new template and no extra adjustment required. It only takes three minutes to finish quality standard set-up. Automatic adjustment of feeding width and variable data inspection position. Operator can change to a new job within 15 minutes.

- Precise

It can inspect point defect of minimum 0.1mm² size and streak of 0.07mm width in the speed of 300m/min.

- Highly Intelligent

Support for automatic positioning and text extraction, and able to set different inspection precision for different areas. Equipped with surveillance system to insure automatic stop when accident occurs to reduce maintenance cost and safety.

4.Advanced Mechanical Design

Marble structure design ensures highly stable equipment running and precise inspection. and our brand new innovative feeding structure design can prevent 95% of scratch issues.

| Model | PrintMan-350S | PrintMan-550S | PrintMan-650S | PrintMan-800S | |

| Application | pharmaceutical packaging, tobacco packaging, 3C electronic products packaging, cosmetic packaging, food packaging, liquid packaging etc. | ||||

| Max. sheet size | 350 x 480 mm | 550 x 420 mm | 650 x 500 mm | 800 x 800 mm | |

| Min. sheet size | 30 x 50 mm | 90 x 90 mm | 90 x 90 mm | 180 x 150 mm | |

| Paper weight in grams | 90 – 350 gr/sq. m | 90 – 350 gr/sq. m | 90 – 350 gr/sq. m | 100 – 450 gr/sq. m | |

| Stable inspection speed | 210 m/min | 250 m/min | 250 m/min | 150 m/min | |

| Min. spot defect accuracy | 0.03 sq. mm | 0.09 sq. mm | 0.13 sq. mm | 0.06 sq. mm | |

| Min. line defect accuracy | 0.09 x 5 mm | 0.14 x 5 mm | 0.16 x 5 mm | 0.12 x 5 mm | |

| Mis-regestration accuracy | 0.09 mm | 0.14 mm | 0.16 mm | 0.13 mm | |

| Color variation | ΔE≥3 | ||||

| Feeding method | Friction feeder | Yes | Yes | Yes | Yes |

| Suction feeder | Optional, intermittent feeding | Optional, unntermittent feeding | Optional, unntermittent feeding | No | |

| Feeder | Optional | No | No | No | |

| Reverse paper feeding | Yes | Yes | Yes | Yes | |

| Elimination method | Air blow | Yes | Yes | Yes | Yes |

| Reverse turning | Optional | Optional | Optional | Optional | |

| Accepted products handling | Single stream | Yes | Yes | Yes | Yes |

| Equipment weight | About 3 tons | About 3 tons | About 3 tons | About 3 tons | |

| Machine dimensions | 6300 x 2680 x 1800 mm | 6900 x 3000 x 2200 mm | 1000 x 3000 x 2170 mm | 1000 x 3200 x 2000 mm | |

| Control cabinet for inspection | 700 x 700 x 1200 mm | 700 x 700 x 1200 mm | 700 x 700 x 1200 mm | 700 x 700 x 1200 mm | |

| Control cabinet for machine | 5300 x 1000 x 1800 mm | 6800 x 1350 x 2200 mm | 9400 x 1600 x 2170 mm | 9500 x 1950 x 2000 mm | |

| Power supply | Three phases and five wires AC380, 50Hz | Three phases and five wires AC380, 50Hz | Three phases and five wires AC380, 50Hz | Three phases and five wires AC380, 50Hz | |

| Power | 13 Kw | 15 Kw | 21 Kw | 20 Kw | |

| Compressed air requirement | ≥ 0.8 MPa | ≥ 0.8 MPa | ≥ 0.8 MPa | ≥ 0.8 MPa | |