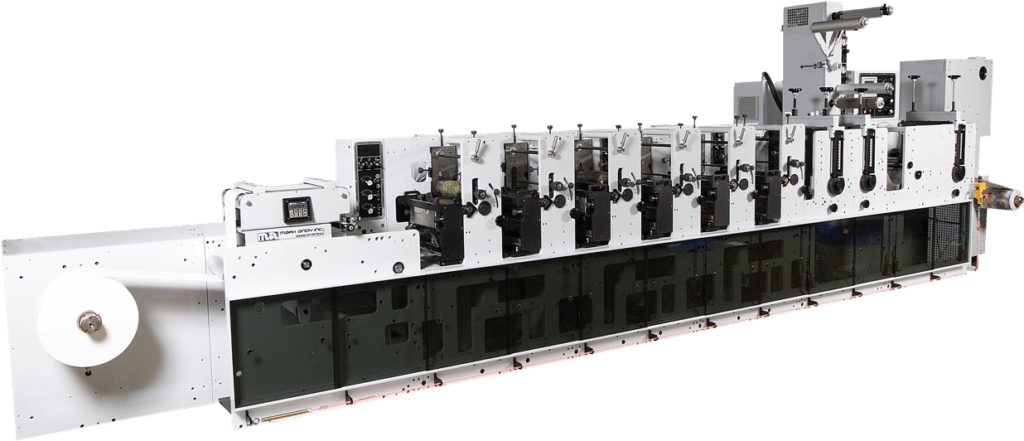

Mark Andy Versa Max

21/12/2020

Mark Andy 2200

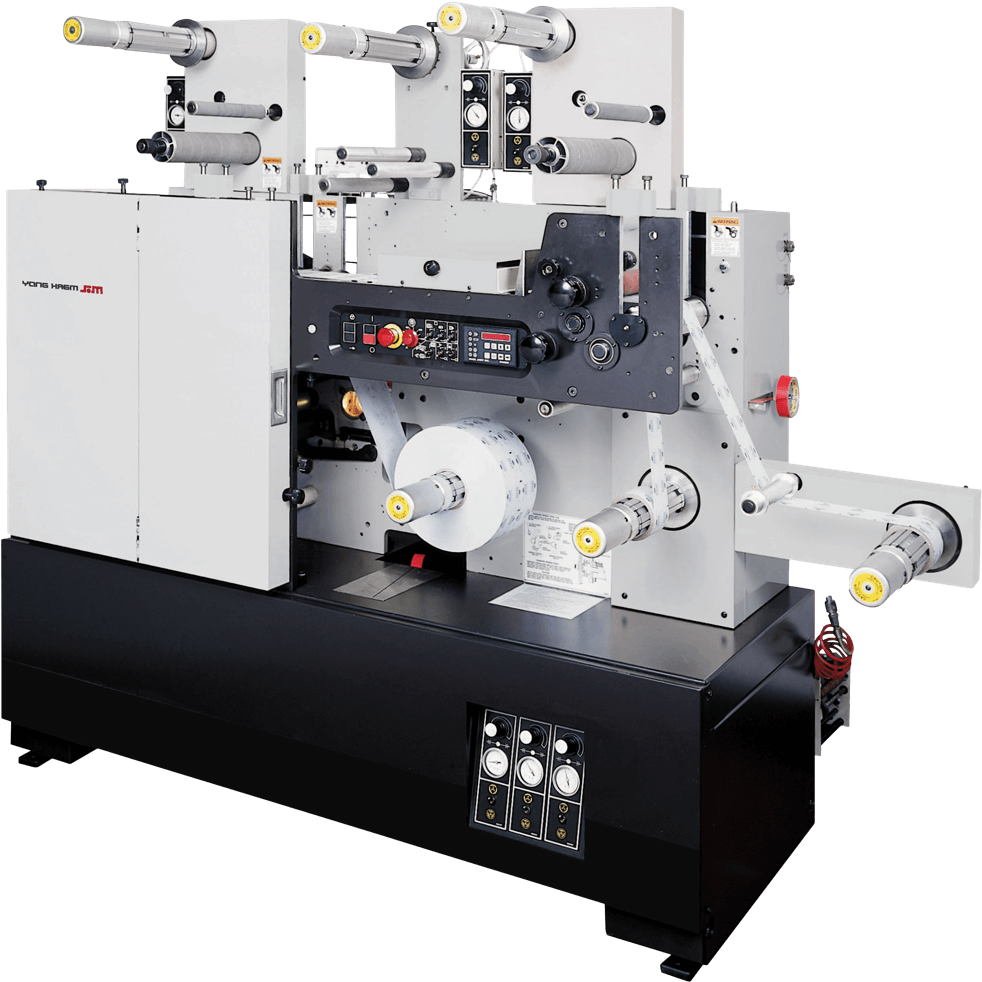

21/12/2020Mark Andy 830

Compact Design. Economic Efficiency.

The Mark Andy 830 was built as a value-add flexographic web converting press for self-adhesive label printing. Operator friendly with convenient access to print stations and press controls, the compact design of the 830 can make a big impact on your bottom line with a small impact on your budget.

830’s accents:

- Produce Prime Labels – 3-color process and lamination outputs conventional prime labels with ease.

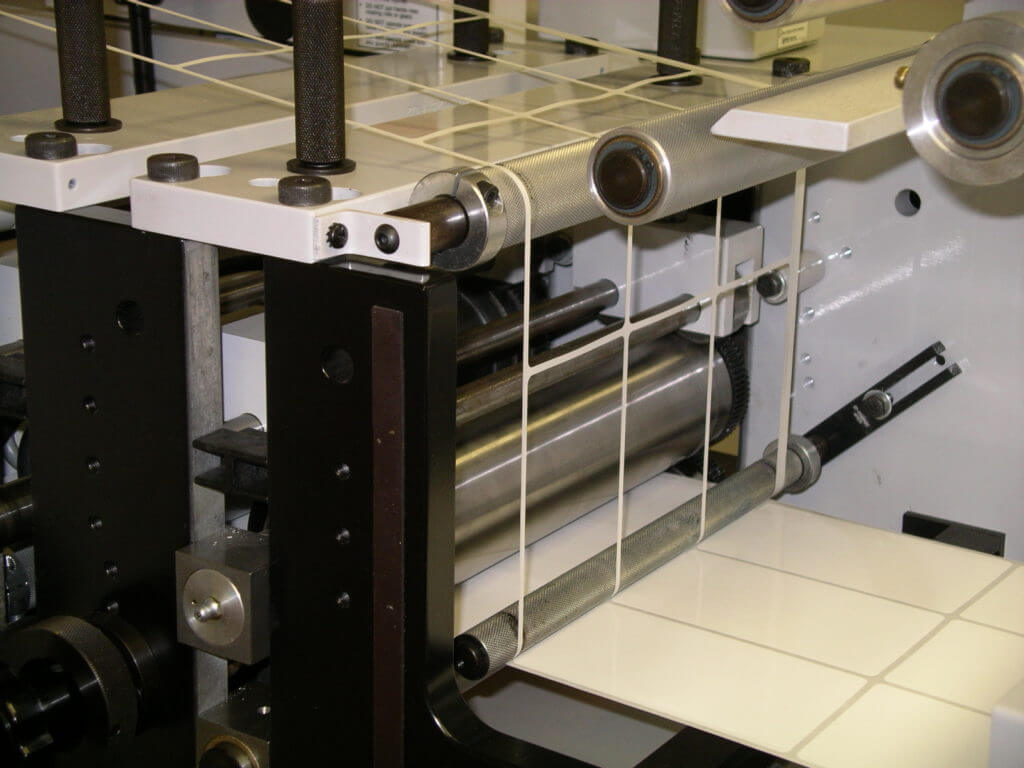

- Robust Features – The 830 is comprised of inline rotary die cutting, a pneumatically controlled waste matrix, dual die stations with underside capabilities and a solid state control drive system.

- Single Pass Converting – Laminate, die-cut, perforate and score inline to streamline workflow and fulfil customer requirements.

- Small Footprint – A standard configuration with minimal space requirements makes an easy integration within any production environment.

Features:

- Drive System – 3hp DC solid state control.

- Gearing – 1/8 inch CP or 32 DP.

- Die Cutting – In-line rotary die cutting.

- Drying & Curing – IR drying.

- Die Cutting – Dual die station with underside capabilities.

- Waste Wind Up – Pneumatically controlled.

- Decoration – Laminator.

Description

| Web Width | 250 mm |

| Max Speed | 91 m/min |

| Substrate Range | 50 – 250 micron |

| Max Die Cut Width | 250 mm |

| Print Repeat Range | 140 – 381 mm |

| Die Repeat (Top) | 102 – 381 mm |

| Die Repeat (Bottom) | 102 – 235 mm |

| Unwind Capacity | 457 mm |

| Rewind Capacity | 457 mm |