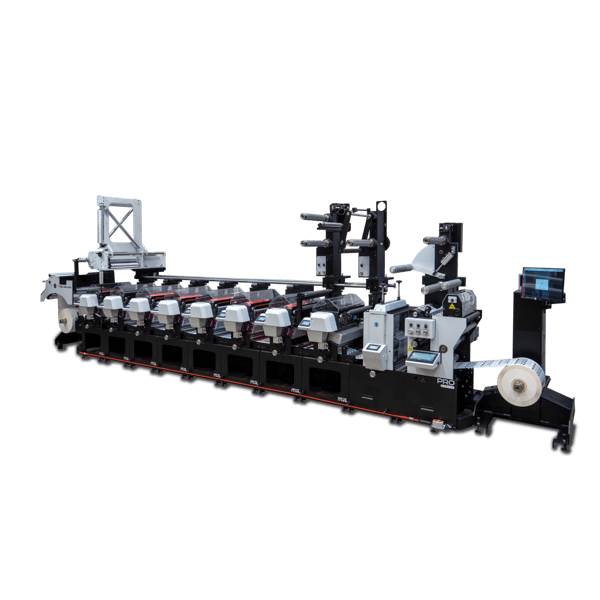

Mark Andy Digital Pro 1

08/12/2020

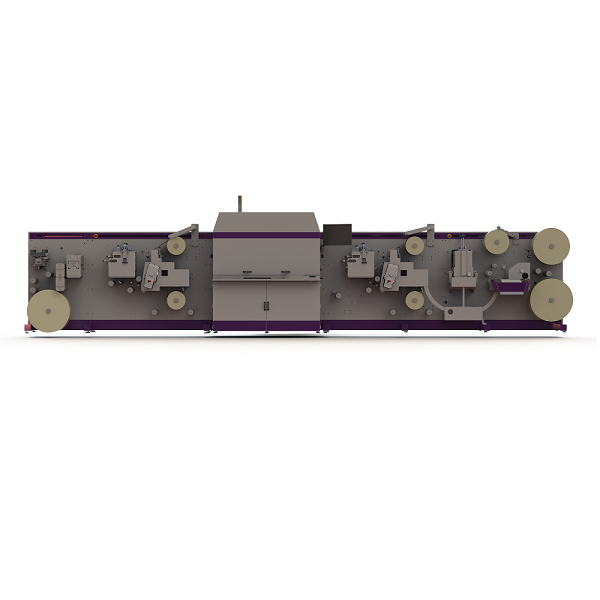

Mark Andy Performance Series E – P9E

11/12/2020Mark Andy Digital Pro 3

Introducing A New Path To Digital Profitability

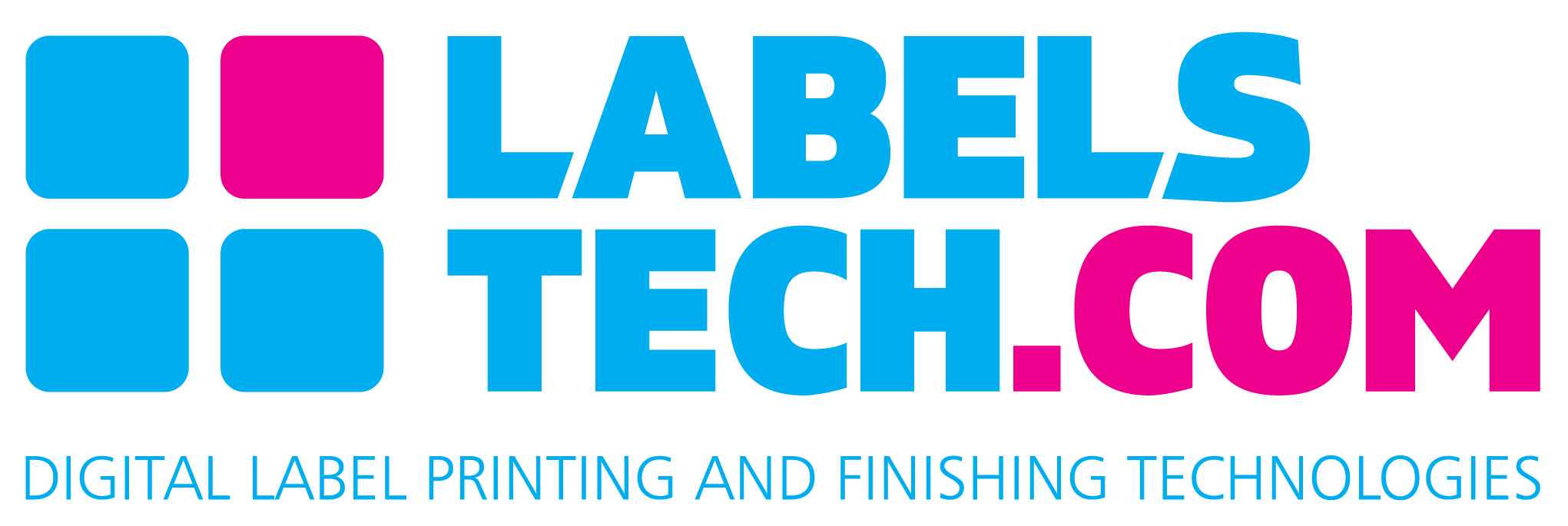

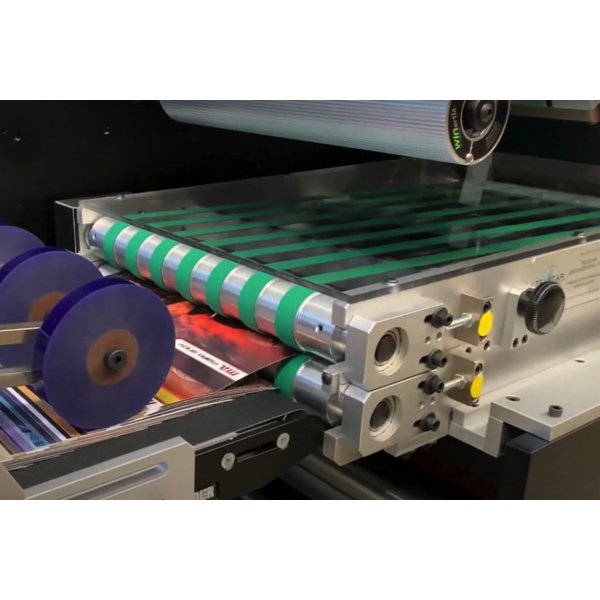

The advanced inline hybrid model, Digital Pro 3 is built for the all-in-one business owner seeking a complete workflow solution. Configurable with conventional or semi-rotary diecutting, and outfitted with a hybrid print station, the Digital Pro 3 is the ideal solution for short-run digital printing.

Digital Pro makes digital printing accessible to global converters. As the entry- and mid-market product family at Mark Andy, Digital Pro delivers low cost to print at high speeds, and the Pro Factor: custom modules that make your Digital Pro, yours.

The PRO factor:

- PROfitability – With a low cost to print at an affordable price point, Digital Pro adds more money to your bottom line, making short-run digital printing an even more attractive target vertical for your operation.

- PROductivity – True 77 fpm makes this machine the most productive small format digital product in the industry.

- PROmise – Our experienced team provides the tools, training, supplies and dedicated resources to make the decision to partner with Mark Andy for a digital press an easy one.

- PROpel – Additional models and configuration flexibility provide the best path to print to propel your business forward, with decision-making and production easier than ever before.

Description

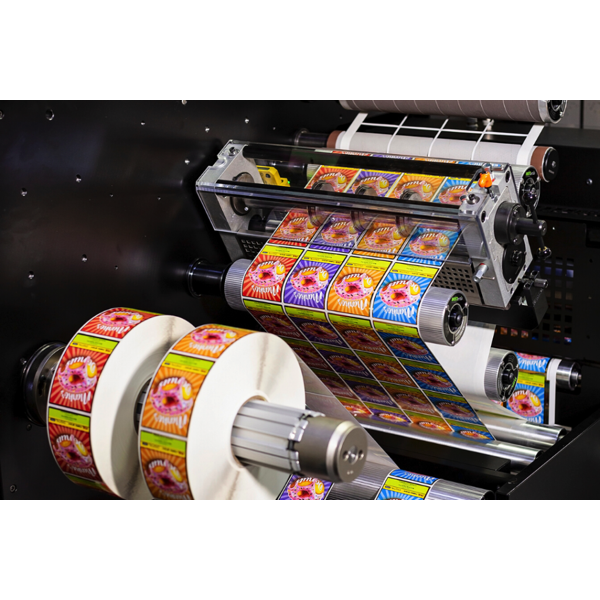

| Printing Process | CMYK Dry Toner Electrophotography Capable of Flexo Reinsertion |

| Speed | 77 fpm (23.4 mpm) |

| Print Repeat | 7-48 inch (178-1195 mm) digital banner mode |

| 7-18 inch (178-457 mm) flexo | |

| Die Repeat | 8.5 inch (216 mm) min |

| 19 inch (482.6 mm) max | |

| Supported Material | Paper, BOPP, PET, PP, unsupported paper, tag stocks, vinyl, foil Approved media list available upon request |

| Material Width | 7-13 inch (178-330 mm) material |

| 4.5 inch (114 mm) accepted for Roll-to-Roll | |

| Print Width | 12.5 inch (318 mm) max digital print width |

| 13 inch (330 mm) max flexo print width | |

| Roll Capacity | 30 inch (762 mm) unwind |

| 20 inch (508 mm) single or dual rewind | |

| Power Requirements | 208/220/240 volt – single phase, 30 amp |

| 208/220/240 volt – single phase, 40 amp | |

| 208/220/240 volt – three phase, 20 amp | |

| Curing & Drying | Air-cooled UV LED |

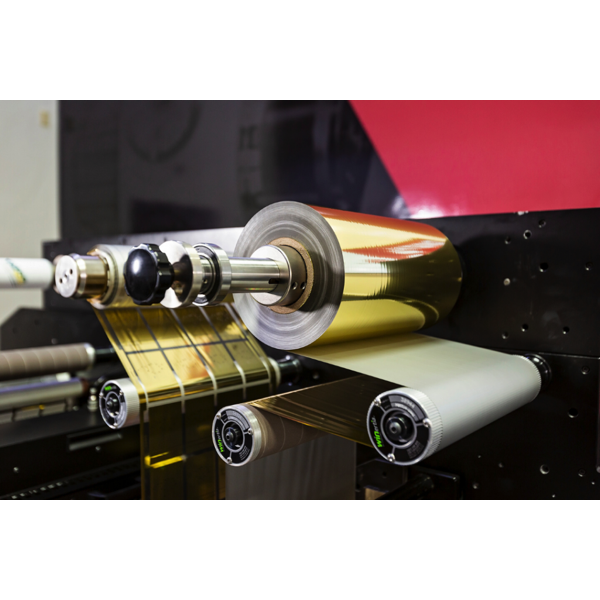

| Converting and Finishing Options | Offline Finishing |

| Conventional Die Station | |

| 19” Semi Rotary Die Station | |

| Single Hybrid Print Station | |

| Hybrid Print Station Before Digital Module | |

| Hybrid Print Station After Digital Module | |

| Sheeter Stacker Conveyor | |

| Bypass Module | |

| Crush Knife Assembly for Slitting |