Mark Andy 2200

21/12/2020

D.P.R GEMINI GMN60 – DIGITAL FINISHING SYSTEM FOR SHEETS FORMAT B2

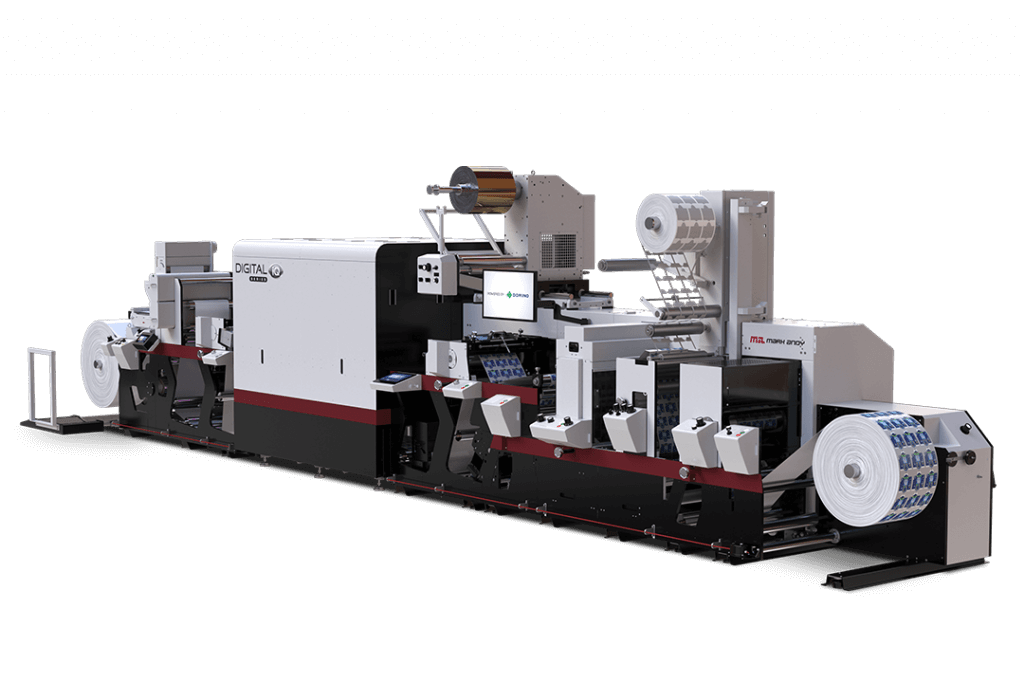

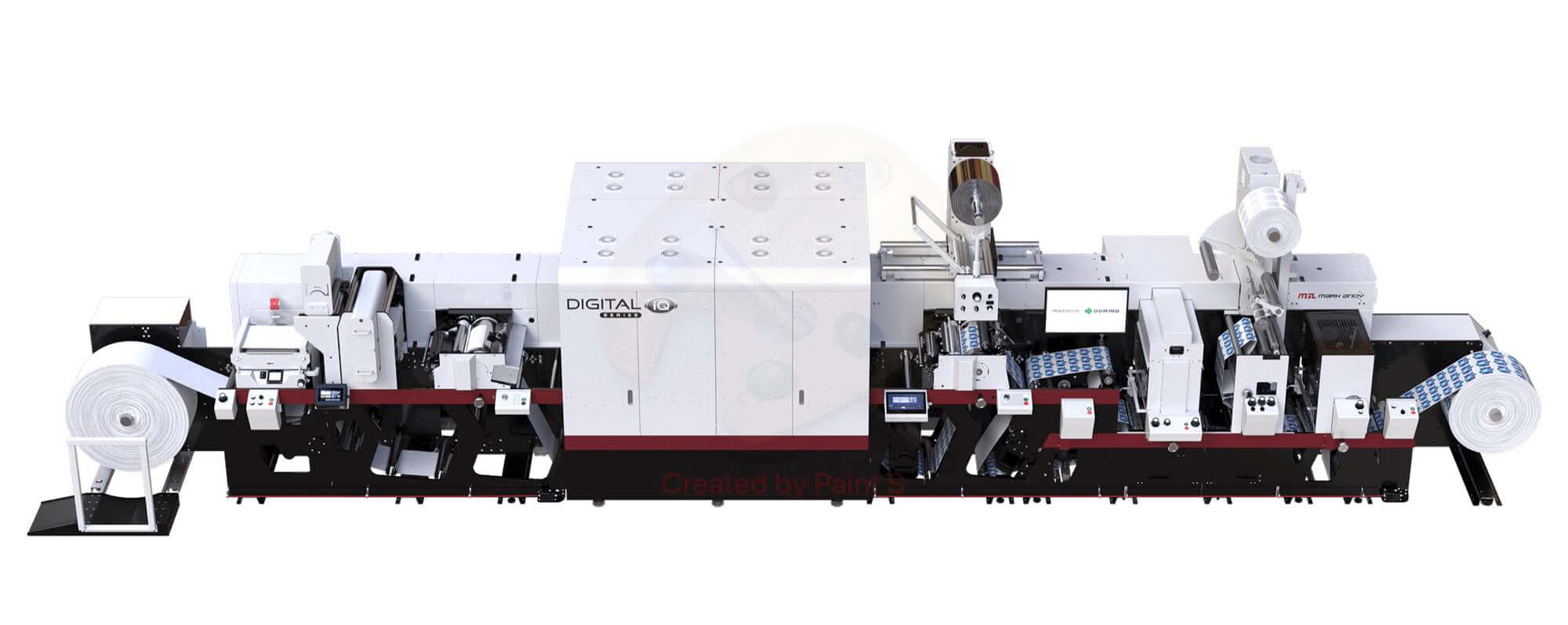

18/02/2021Mark Andy Digital Series iQ

Hybrid Integration Made Intelligent

When digital printing is no longer enough to separate you from competition and jobs require inline finishing to be profitable, a production-level digital hybrid solution that offers flexibility is key.

The smart choice for your business, Digital Series iQ is a fully-integrated inkjet press built on a proven Evolution Series flexo platform. Powered by a robust Domino N6101i UV inkjet module, it boasts digital brain power and Mark Andy converting excellence.

Digital printing features:

i-Tech ActiFlow – Protects nozzle performance by eliminating air bubbles through an ink circulation system that keeps the print chemistry continuously moving around the head even when printing has stopped.

i-Tech CleanCap – Automatically cleans printheads, eliminating daily manual wiping and prolonging the life of your machine.

i-Tech TrapLess – Reduces the risk of ink conglomeration, preventing nozzle failure.

i-Tech UltraMix™ – Ensures continuous white ink circulation to guarantee the pigment remains in suspension all the time.

Hybrid platform features:

Web Conditioning Processes – Optimize substrates for production in a single pass.

Film Capable – Enabled to offer high-quality film labels through chilled impression rolls and static bar additions.

Embellish Labels Inline – Multi-use print stations enable laminates, flexographic spots, varnishes, adhesives, and more.

Minimal Changeover Time – With VDC-SR, your bottom line continues to benefit from the speed of digital while experiencing increased operator ergonomics between job.

| Printing Process | CMYK +WW UV Inkjet Powered by Domino; (OV Upgrade Available) |

| Resolution | 600 x 600 dpi native Kyocera print heads |

| White Ink Opacity | 72% Opacity |

| Speed | High-Quality Mode: Up to 164 fpm (50 mpm); High-Speed Mode: Up to 230 fpm (70 mpm) |

| Workflow | Esko DFE; Mark Andy ScreenPro |

| Web Width | 13 inch (330 mm) max; 8 inch (203 mm) min |

| Die Repeat Range | 24 inch (610 mm) maximum repeat in full rotary or semi-rotary mode |

| Substrate Range | Pressure sensitive papers and films, unsupported papers & films, tag stocks, light carton and more |

| Drying & Curing | UV |

| Roll Capacity | Unwind and rewind: 40” diameter (1000 mm); Maximum roll weight: 100 lbs (300 kg) |

| Environment | Optimal temperature range: 68-72°F (20-22˚C) |

| Ink Storage: 68-77°F (20-25˚C) | |

| Humidity level range: 40-60% | |

| Dust controlled environment |